Click on image for full screen view.

Location: Half Moon Bay near the California coastline south of San Francisco with mild temperate weather. Summer mornings often covered with a marine fog layer, but winter is milder than inland California.

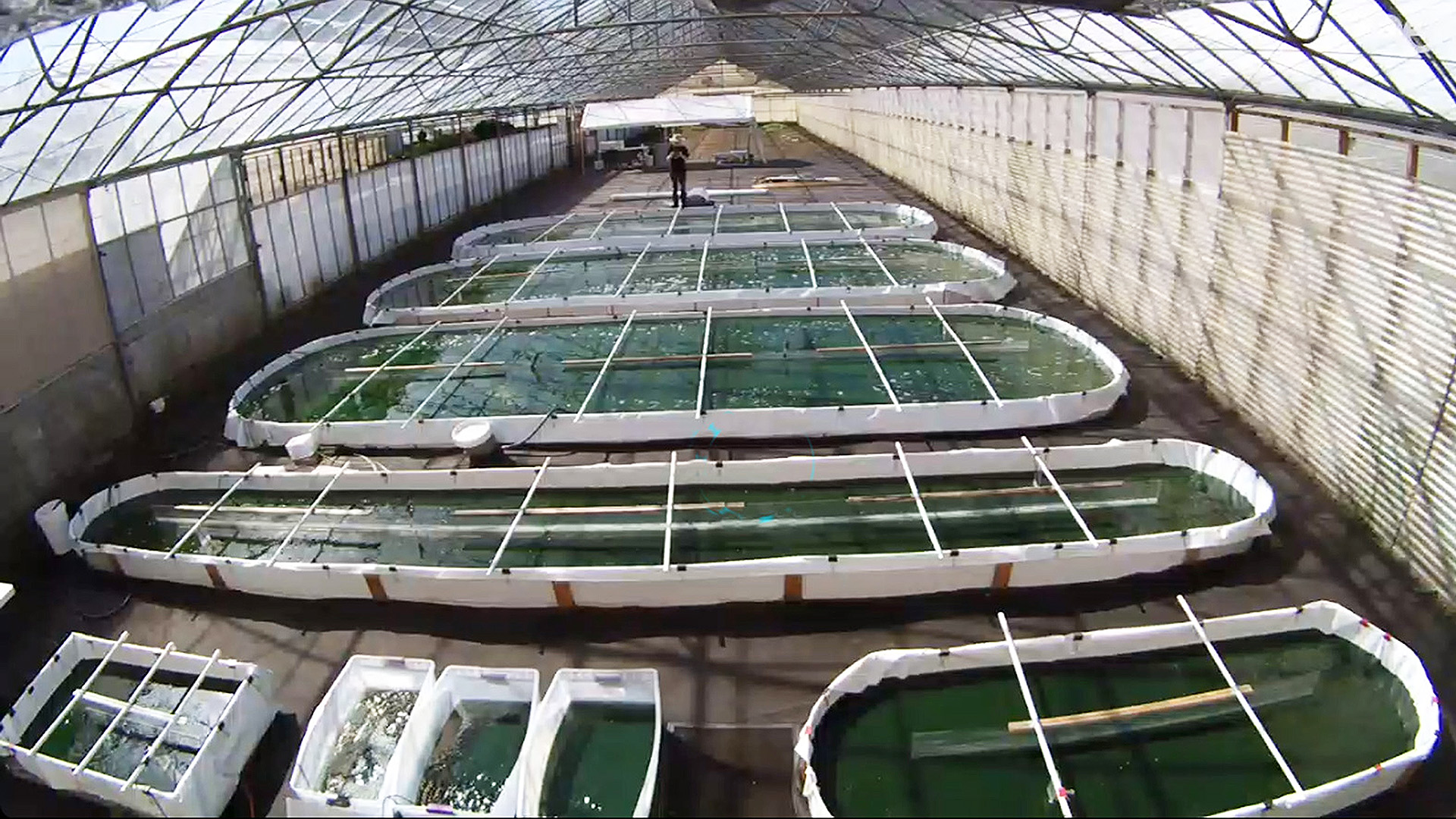

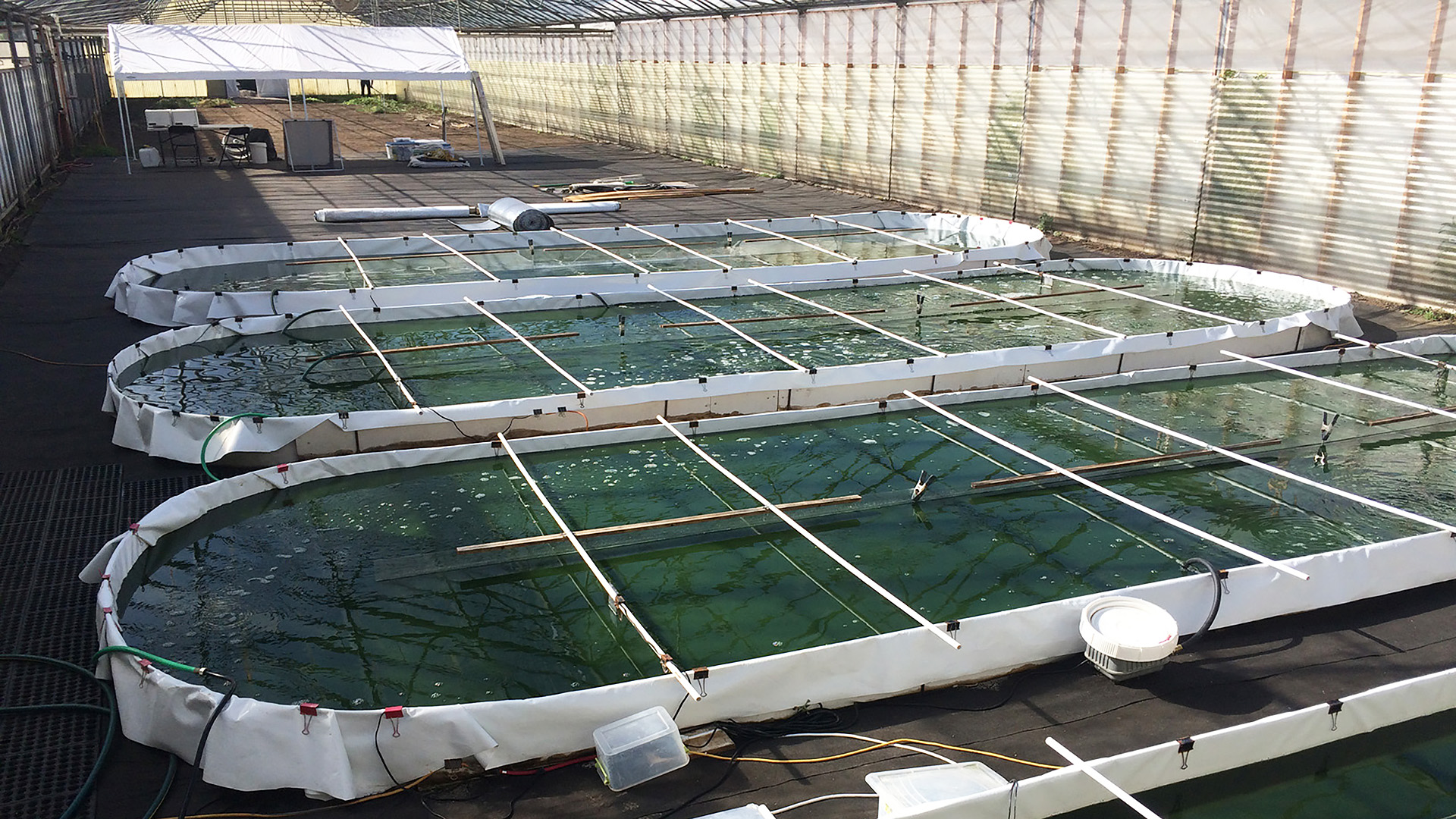

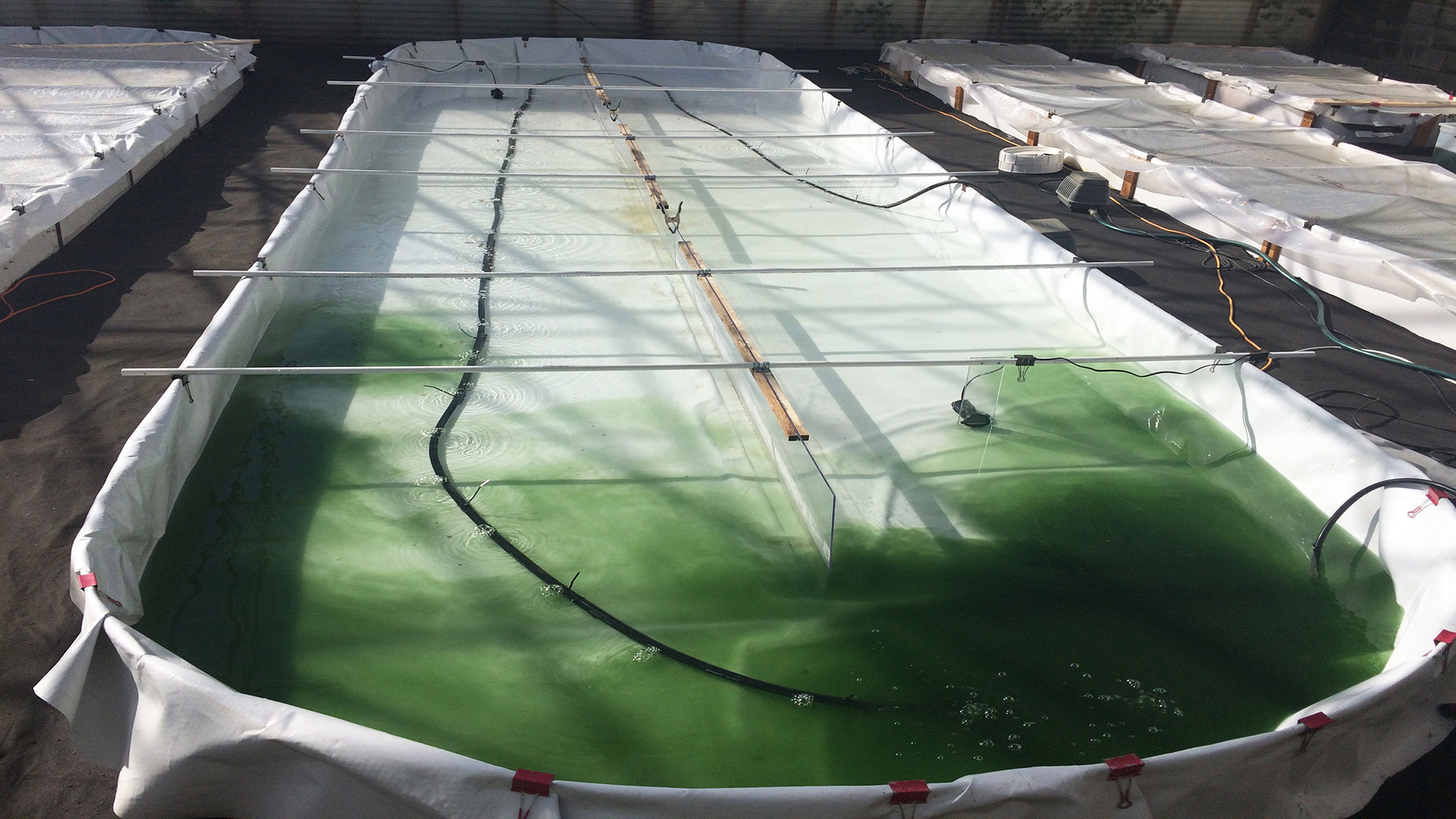

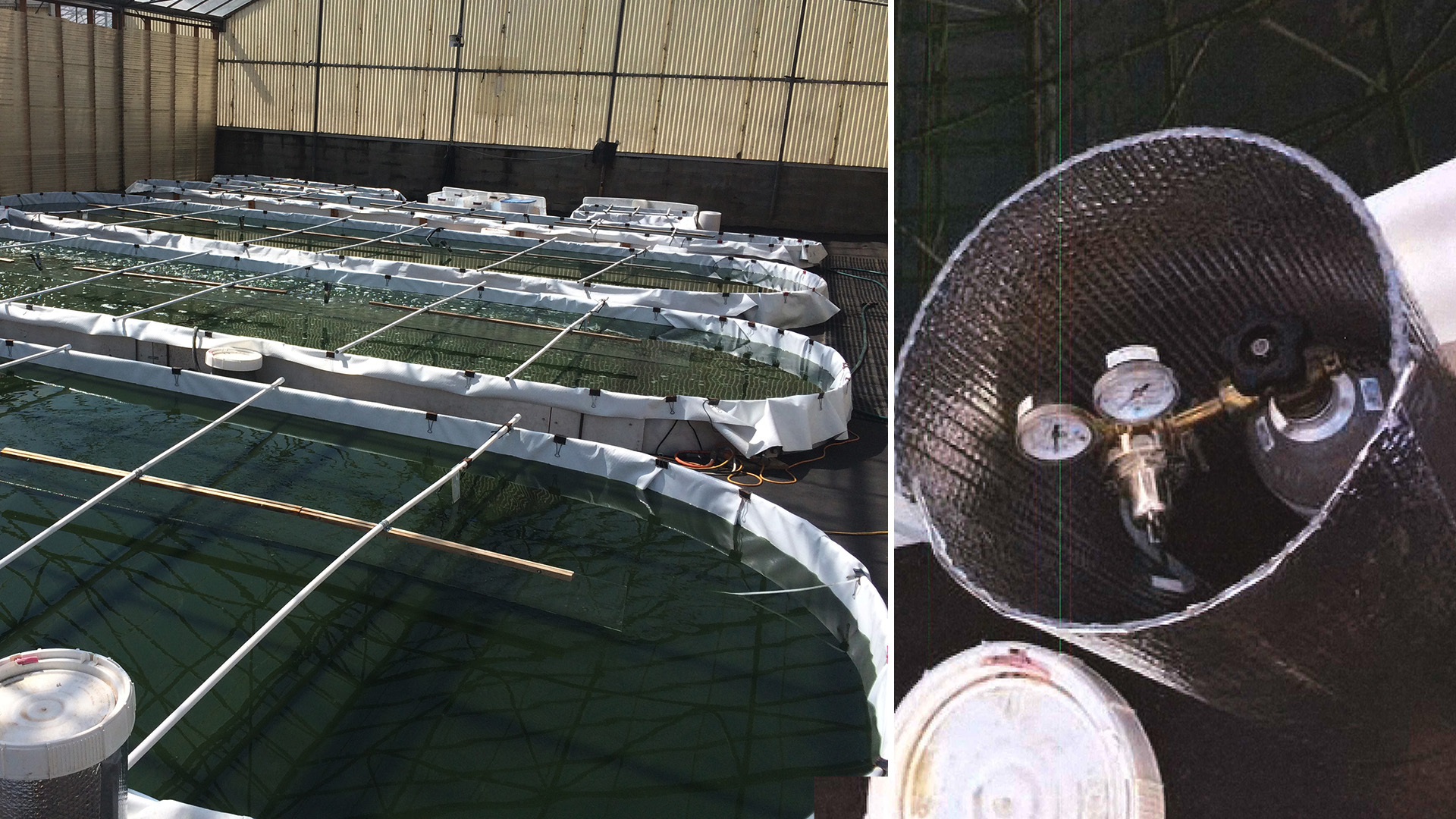

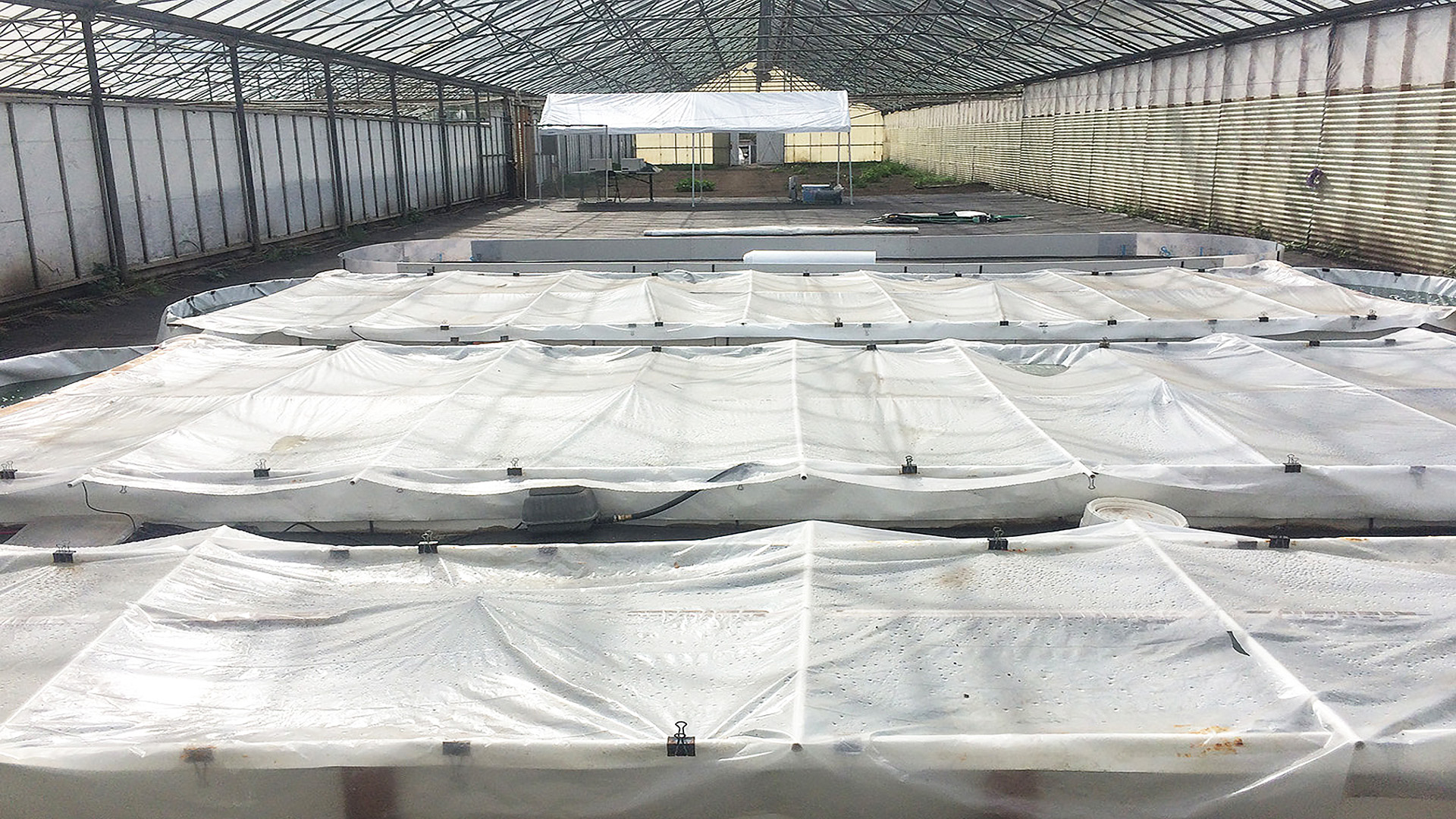

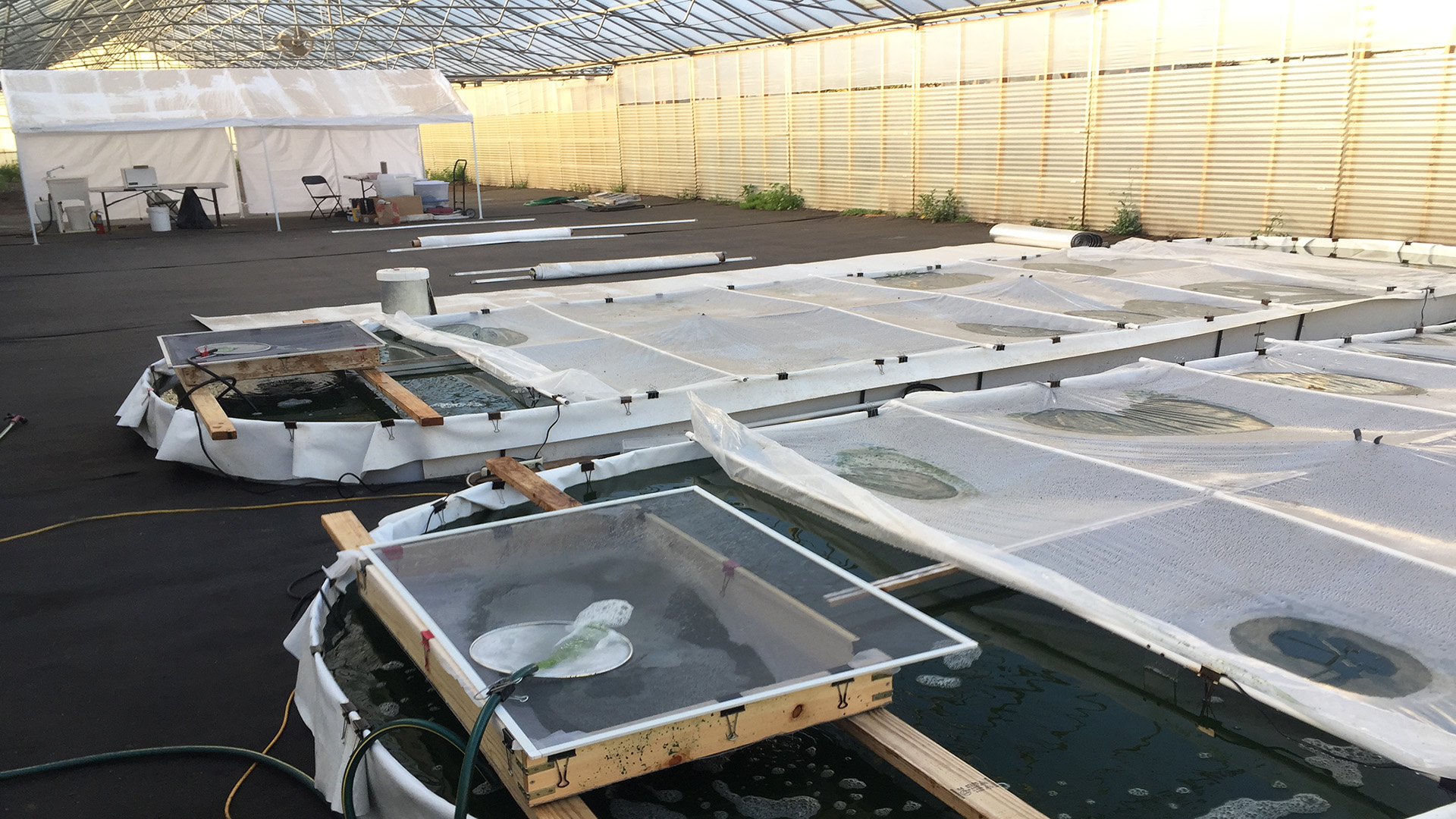

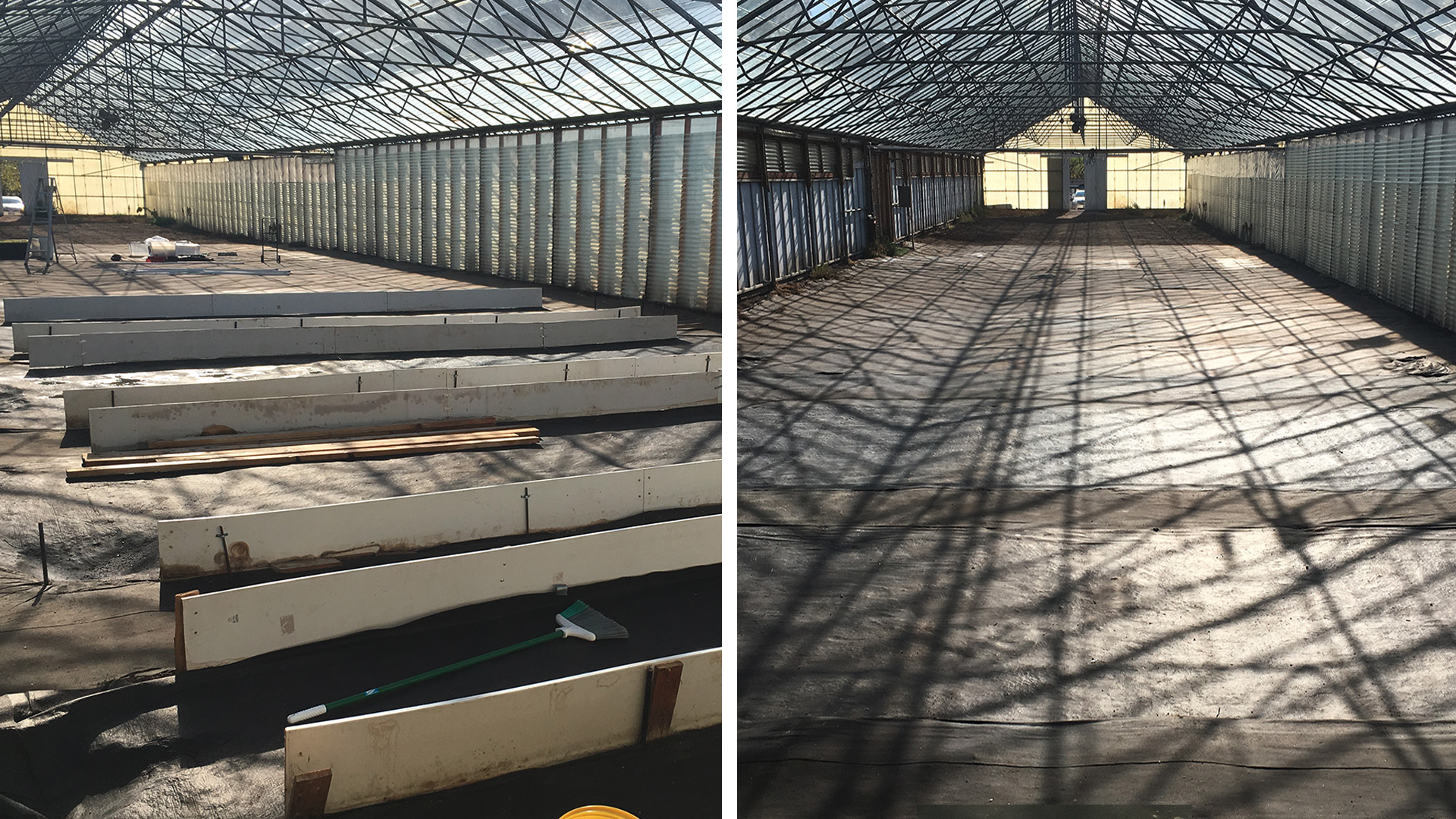

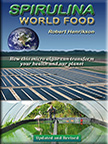

Infrastructure: This spirulina microfarm was built inside a large commercial glass greenhouse once used for growing flowers. The ground was slightly graded to be flat. Water, power and internet available.

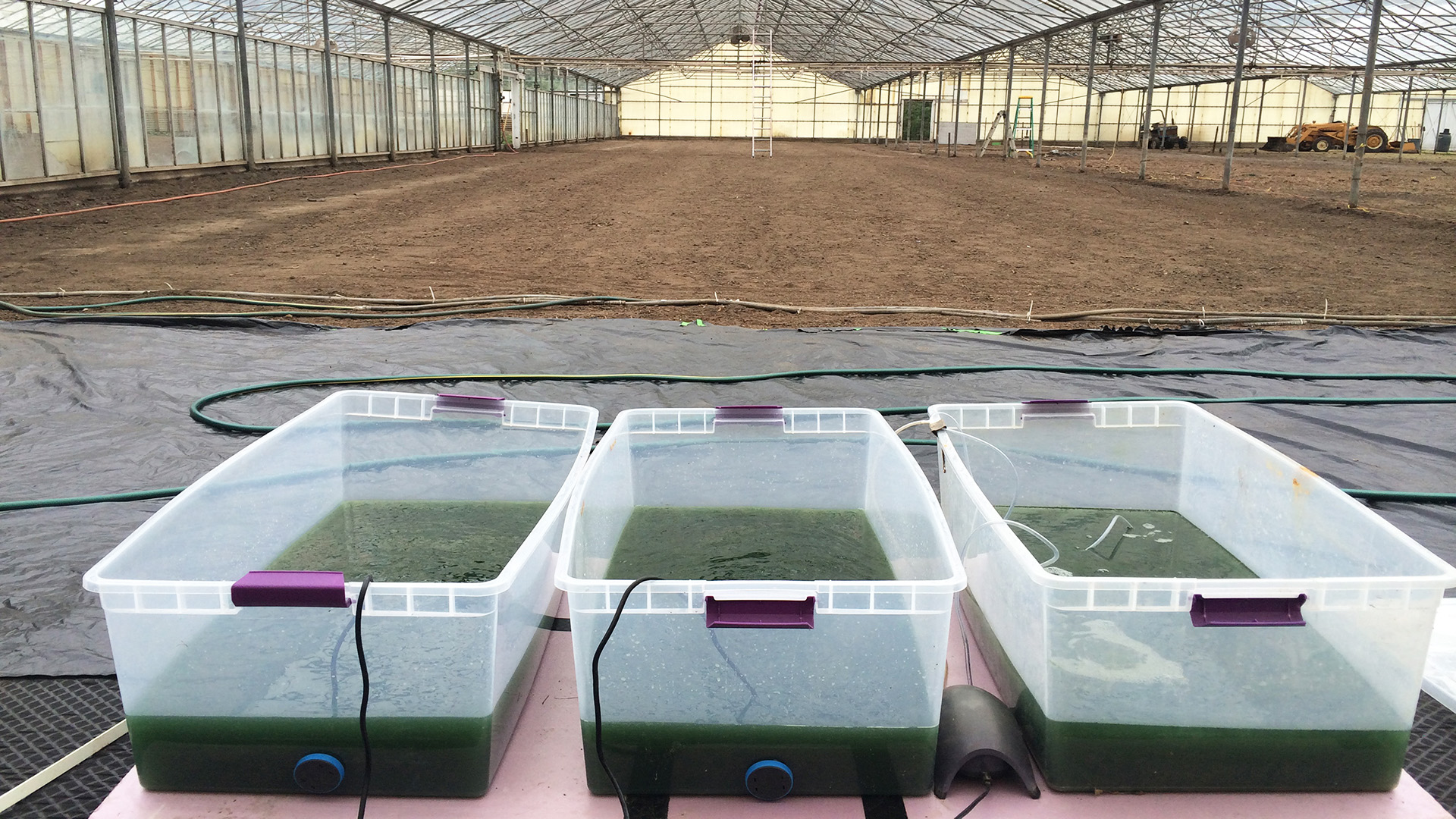

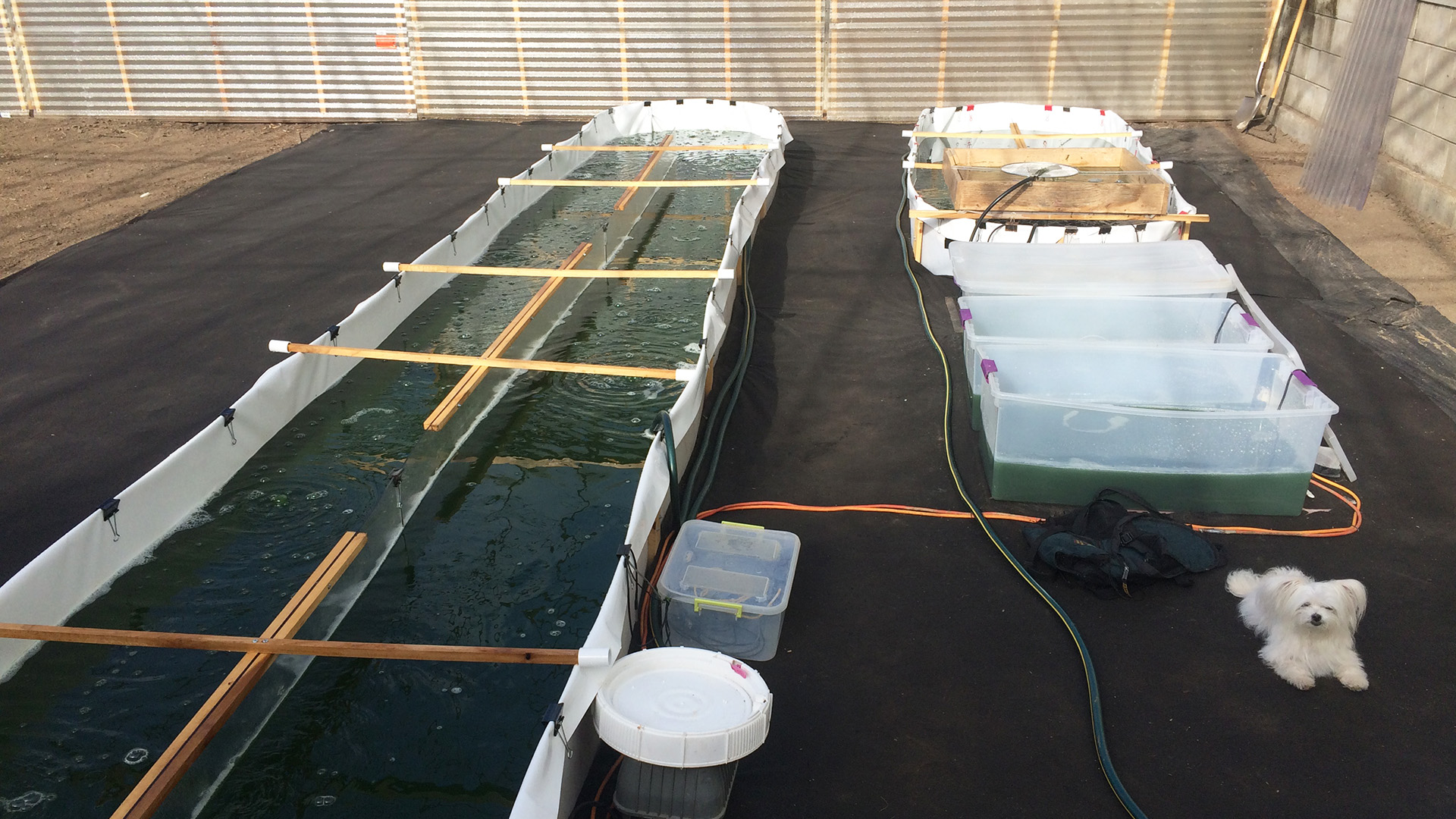

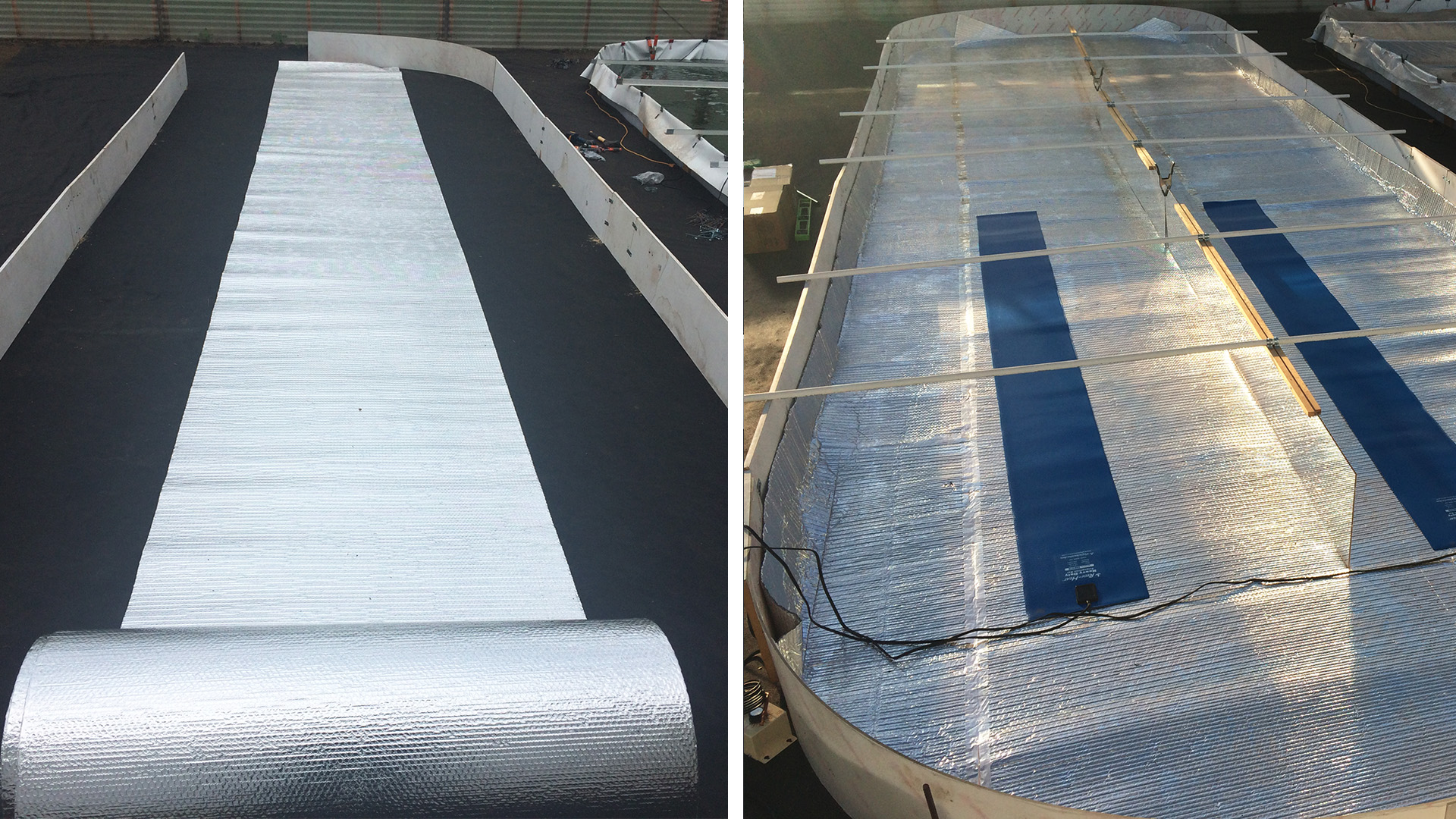

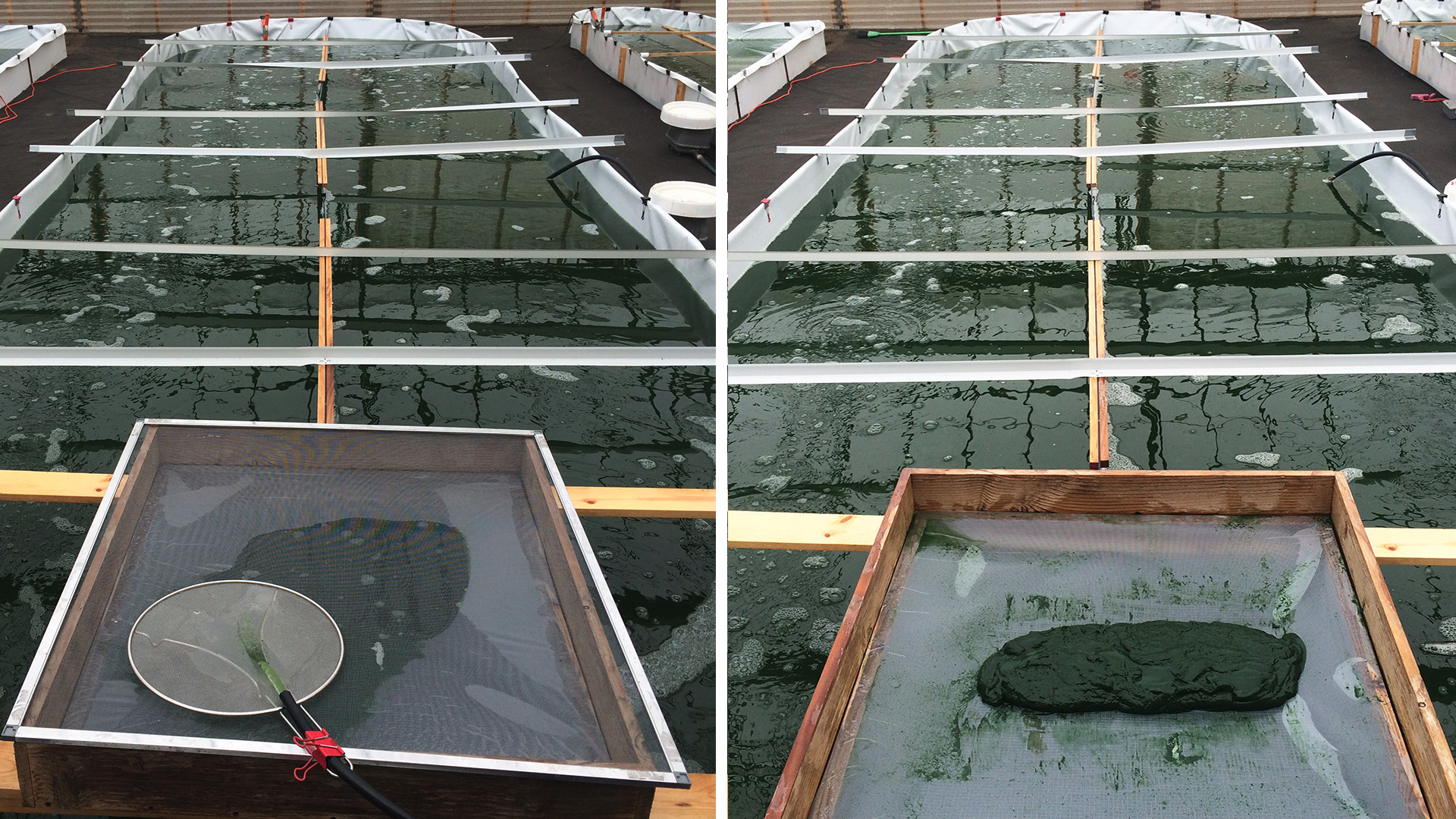

Microfarm Design: There are different microfarm designs and materials. This one was designed as a low cost modular, replicable system, using common materials, easy to install and disassemble. No excavation or cement required. Built with small culture scale-up tanks and ponds, then a series of flat bottom production ponds with small circulation pumps, instead of paddlewheels, to move water around the raceways.

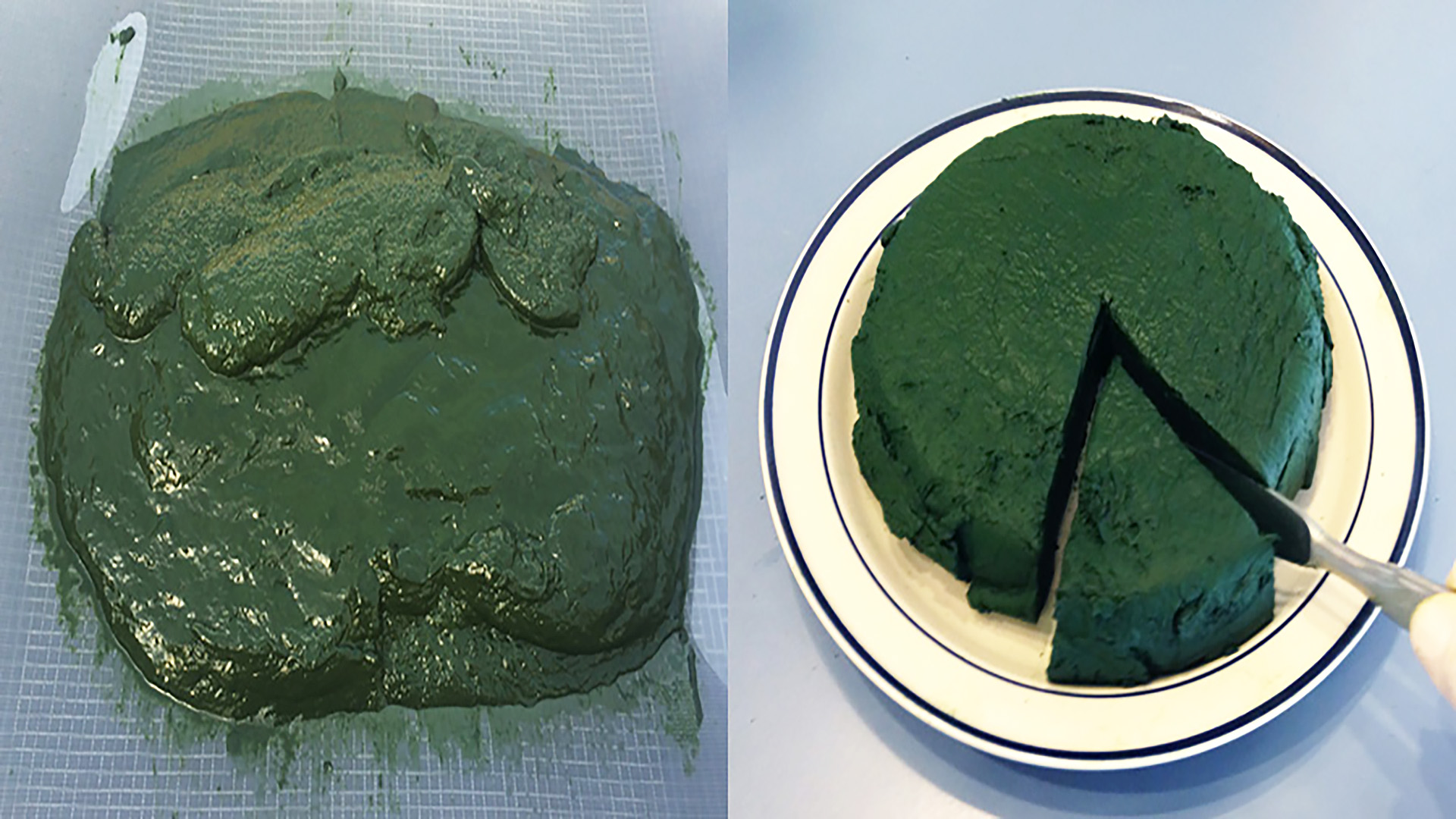

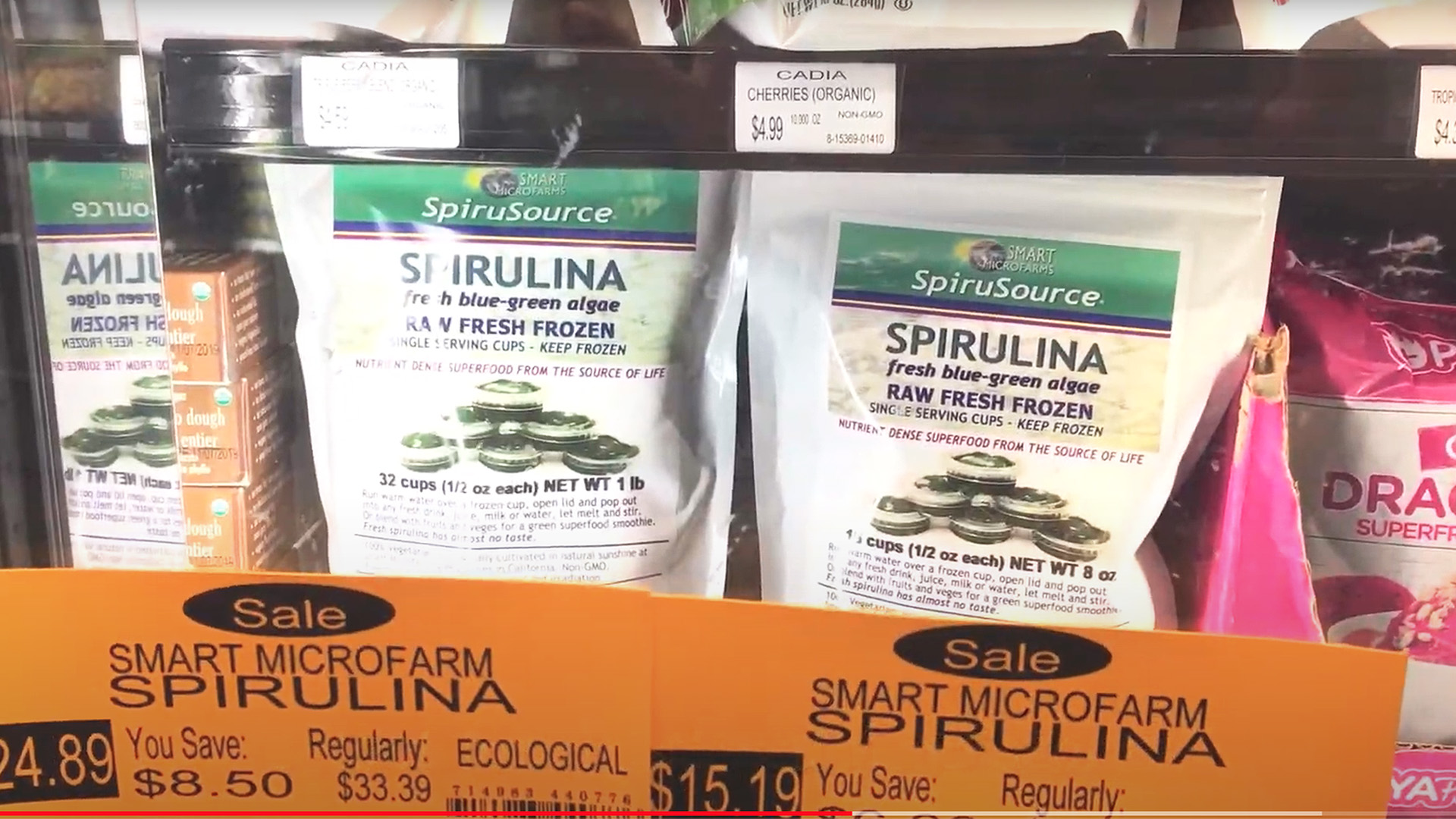

Operations: From 2016-19 this microfarm produced all-natural spirulina 12 months a year in a semi-controlled environment, using no pesticides, herbicides or fungicides. Water source was carbon filtered. Harvesting several days a week in the spring, summer and fall growing seasons, much less often in winter. Low temperature dehydration on site. Fresh and frozen processing and packaging off site.Marketing: Products were branded as SpiruSource® and packaged fresh, frozen or dehydrated. With a Certified Producer Certificate for the California Farmers Market Program, SpiruSource® products were sold in Bay Area farmers markets. Also sold in select natural food stores, direct to local customers and online.

Customers: Many customers prefer fresh spirulina to traditional spray dried powder. Fresh and frozen have almost no taste, and can be mixed with drinks and foods without changing the flavor. Low temperature dehydrated spirulina sold as cruchies or powder has a mild and delightful umami flavor. Appeals to locavores, fresh food and raw food consumers.